Glass cutting machines are essential tools in the glass industry. From custom mirrors to table tops and windows, glass is used in various applications. But, cutting glass manually is a time-consuming process that requires a lot of skill and patience. This is where glass cutting machines come into play. A glass cutting machine can cut large sheets of glass into different shapes and sizes, delivering precise results in a fraction of the time it takes to do the same work by hand.

This blog will dive deep into glass cutting machines, how they work, the different types available, and their uses.

How do Glass Cutting Machines work?

Glass cutting machines operate using a number of different principles, depending on the type of machine. The most common method is called 'scribing and breaking.' The machine uses a diamond wheel to score the glass surface, creating a weakened area along the intended cut line. Then, pressure is applied along the cut line, and the glass breaks along the scored area. The result is a clean, accurate cut with minimal glass waste.

Types of Glass Cutting Machines

There are several types of glass cutting machines available, each designed for specific applications.

1. Manual Glass Cutting Machines - These are the simplest and most affordable types of glass cutting machines. They require manual operation and are mainly used for small-scale glasswork. However, manual machines are extremely precise and allow the operator to control the cutting process completely.

2. Semi-Automatic Glass Cutting Machines - In semi-automatic glass cutting machines, the operator guides the glass through the machine while the machine’s mechanisms score and break the glass. This type of machine is ideal for medium to large-scale glasswork.

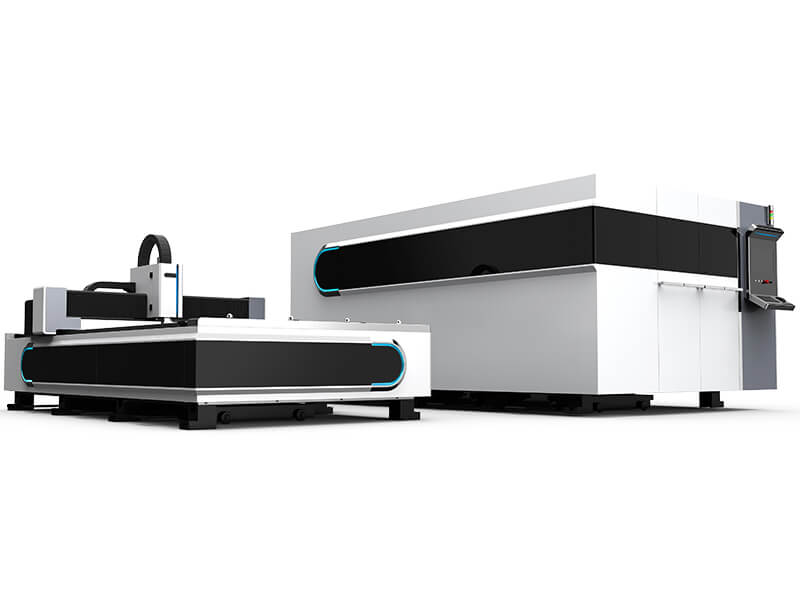

3. Automatic Glass Cutting Machines - Automatic glass cutting machines are the most advanced machines in the market. They can cut large quantities of glass in a short time, and the operator only has to load and unload the glass. These machines are computer-controlled, and they can cut complex shapes and designs with incredible accuracy.

Uses of Glass Cutting Machines

Glass cutting machines are used in various industries, including the automotive industry, construction, and interior design. Some common applications include:

1. Cutting Glass for Windows - Glass cutting machines are used to cut large sheets of glass into sections for windows.

2. Mirrors and Glass Table Tops - Glass cutting machines are used to cut mirrored glass and glass table tops to specific sizes and shapes.

3. Glass Art and Sculptures - Glass cutting machines are used in the art industry to create intricate designs and unique shapes.

Conclusion

A glass cutting machine is an essential tool in the glass industry. It offers fast, accurate, and precise cutting of glass sheets to any desired size and shape. Depending on the scale and nature of the work, a manual, semi-automatic, or automatic glass cutting machine may be the best fit. With the right machine, any glass cutting job is made easier and faster. Don’t compromise on quality when it comes to glass cutting machines, and choose reliable brands that offer the best quality, efficiency, and service.