Introduction:

In the fast-paced manufacturing industry, efficiency plays a critical role in delivering high-quality products. When it comes to hose assembly production, using efficient tools like aluminum crimping machines can lead to significant time and cost savings. In this blog post, we will delve into the features and benefits of aluminum crimping machines, their applications, and how they optimize the hose assembly process. So, let's dive in!

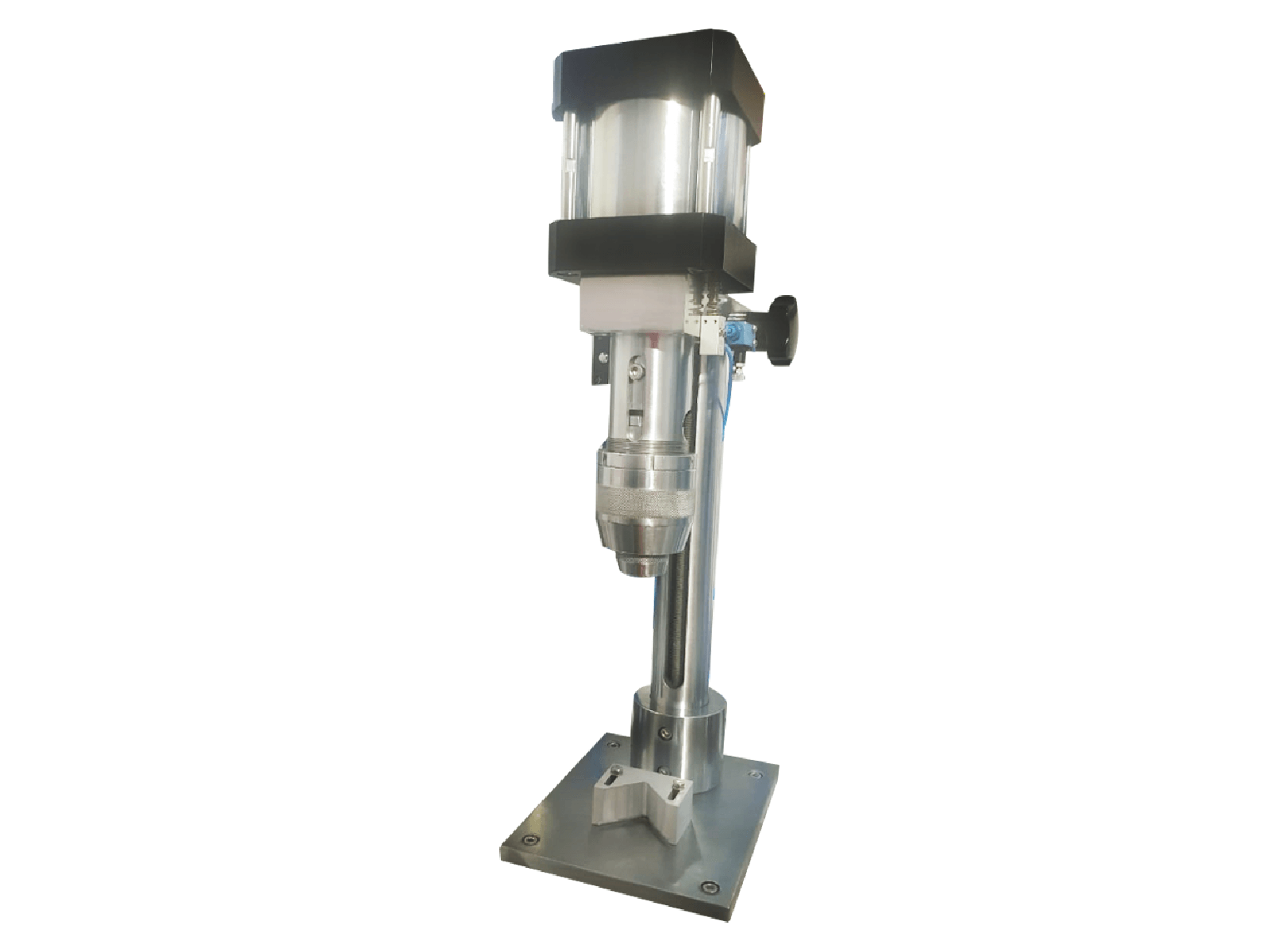

Understanding Aluminum Crimping Machines:

Aluminum crimping machines, as the name suggests, are specifically designed to make hose assembly and connect various sizes of hoses with ease. These machines are equipped with advanced technology and robust mechanisms that ensure precise crimping, reliable connections, and enhanced efficiency in hose assembly production.

Key Features and Benefits:

1. Precise Crimping: Aluminum crimping machines provide precise and consistent crimping, ensuring secure connections between hoses. This feature eliminates the risk of leakage and enhances overall product quality, reliability, and customer satisfaction.

2. Time and Cost Savings: With their rapid crimping capabilities, aluminum crimping machines significantly reduce production time, enabling manufacturers to meet tight deadlines and increase output. Additionally, by streamlining the assembly process and minimizing human error, these machines ultimately reduce labor costs.

3. Versatility: These machines offer versatile functionalities by accommodating hoses of various sizes. Whether it's for heavy-duty applications or smaller projects, aluminum crimping machines can handle a broad range of hose sizes, adapting to diverse production needs.

4. Enhanced Safety: By automating the crimping process, aluminum crimping machines eliminate the need for manual labor, reducing the risk of injuries and accidents associated with traditional crimping methods. This leads to a safer working environment, ensuring the well-being of workers.

Applications of Aluminum Crimping Machines:

Aluminum crimping machines find applications in a multitude of industries where hose assemblies are crucial. Some notable examples include:

1. Automotive Industry: These machines are extensively used for crimping hoses in automotive systems. From power steering systems to fuel lines and brake systems, aluminum crimping machines ensure secure connections that contribute to the smooth functioning of vehicles.

2. Aeronautics and Aerospace: In the aerospace industry, where precision and reliability are paramount, aluminum crimping machines are used to assemble hoses in hydraulic and fuel systems. Such machines guarantee high-quality connections that meet strict industry regulations and support the safe operation of aircraft.

3. Construction and Mining: Hydraulic hoses play an essential role in heavy machinery used in construction and mining sectors. Aluminum crimping machines skillfully crimp hoses that withstand the demanding environments and high-pressure conditions of these industries, ensuring optimal performance and durability.

4. Industrial Manufacturing: In many industrial manufacturing processes, hoses are used to transport fluids, chemicals, and various substances. Aluminum crimping machines contribute to the seamless operation of these production systems by providing secure connections for hoses used in diverse applications.

SEO Keywords: Aluminum Crimping Machine, hose assembly, crimping machines, hose connections, manufacturing industry, precise crimping, time and cost savings, versatile functionalities, hose sizes, enhanced safety, automotive industry, aeronautics and aerospace, construction and mining, industrial manufacturing.

Conclusion:

Investing in an aluminum crimping machine can revolutionize hose assembly production, streamlining processes, improving efficiency, and ensuring reliable connections. With their precise crimping capabilities, time and cost savings, and versatile functionalities, these machines have become indispensable assets in various industries. As technologies continue to advance, manufacturers can expect even more innovations in aluminum crimping machines, empowering them to meet evolving demands and stay ahead in the competitive marketplace.